Beneteau First 210 Tech Notes

Title: Replacing Swing Keel Lifting Mechanism

Author: Terry F. Ellis

This describes what Bob Field (owns 1993 First 21.0 Swing Keel model

Hull #63) did to repair the broken keel lifting screw mechanism on his

F210 (plus comments from a Rod Forman and Jay Harrell regarding the repair

and swing keel lifting apparatus in general):

Terry,

I received your thought provoking note re: keel lift. The one Beneteau

sent me is the "improved " version so I'm sure Ward Richardson could be

aware of the changes. In fact they sent me two and I returned one to Marion

SC. As I explained to Rod Forman, the new one had a longer bronze collar

(more threads?) and what appeared to be a greater pitch (Wider) to the

threads for greater durability. I certainly agree that recognizing a weakness

and high failure rate in the original mechanism, (sufficient to make an

engineering change) they (Beneteau) should at the very least, if not replace

the deficient part, make some cost adjustment, as mine cost $350 plus shipping.

If I can provide any information to them, let me know. Warmest Regards.

Bob Field Hull #63

-----Original Message-----

To: Bob Field & rod forman

Cc: Ward Richardson <ward.richardson@beneteauusa.com>

Date: Friday, November 02, 2001 10:20 AM

Subject: RE: Bob Field's Broken F21.0 Keel Lifting Shaft

I agree with all of your conclusions. Bob Field told me he wanted the

mechanism back so he could make a claim against Beneteau. I think if you

took some pictures of it and mention all of us who witnessed it, that would

be sufficient "evidence" for Beneteau USA. Moreover, I think Beneteau USA

would like for "us" to "reinvent" this keel lifting shaft such that it

would be: a) more durable b) easier to use (i.e. fewer turns up to down)

c)less "clunky" (i.e. have bigger nylon discs to cushion the keel and make

it more "fair" d) cheaper to fix (i.e. just a new "collar" vs. a whole

new worm shaft/rod/collar/shackle e) something that would take up less

space in the cabin (i.e. a "gear" that would come out under the companionway

step or be electronic vs. sticking up right in front of the porta potti

and vee-berth) and f) something that would withstand trailering whether

or not the keel is resting on a trailer support pad (I suspect just the

bouncing of the boat harms the screw mechanism even if/when the keel is

resting properly on it's bunker not to mention I believe a collision of

the keel with a rock under sail can/does damage the lifting worm gear-should

have an "awl" releasing mechanism in the event of a hard blow). I think

you should contact Ward Richardson at Beneteau USA, tell him what we've

discovered and get B to budget money and parts for you to design/produce

a better mechanism. Having said that, I understand that the "new First

211 Spirits" produced/sold only in Europe now, have a better mechanism,

one that was re-designed from the original F21.0 contraption. I understand

it has a better "purchase angle" and a better collar and screw shaft. It

would be good if Ward would order one of those from France and ship it

to you for inspection. I, for one, believe B should offer to replace the

lifting mechanism on every F21.0 sold since the boat was introduced in

1993. There are only about 60 of them around in the USA (40 are fixed keel

"Classic" models like mine). Including labor, the "retrofit" might cost

Beneteau $500 a boat. That's $30,000; not a small sum yet the "right thing

to do" and...what Catalina Yachts would/did do on the mast, mast step,

spreader and forestay chain plate on the Catalina 22s, all of which were

subject to failure in C-22s made from 1970 to 1980...some 9,000 boats!

And here are conclusions made upon inspection of Bob Field's old lifting

screw by Bob Forman, a machinist (who also owns of a Beneteau First Class

8 with similar swing keel/lifting mechanism):

------------

Hi Terry,

I have disected and deseminated the heck out of this thing. The major

faults with it that I can see are:

1: too fine a thread which translates to to thin a thread cross section

ie. structural strength under load especially after wear, I elaborate later.

2: too short an engagement length of thread in the nut which further

reduces structural strength.

3: too small a screw diameter which again reduces available strength

Bob Field told me (my remembrance)that he paid around $350.00 for the replacement.

While he did not examine the new unit with calipers such as I have the

old one he said that there were "visible" differences translating to an

"apparent sense" of a stronger unit. That's tough to quantify. As I said

in earlier posts the design is an improvement in many regards to the earlier

(ala First Class 8) unit that I personally am more familiar with. It is

eveident however that they have had a reasonable amount of previous failures

to warrant an improved unit for more recent models. As designed however

the unit will raise into the cabin, without any damage to the screw mechanism,

when an under water obstacle is contacted with any force. Jay, Niels and

I all noticed this during the the Rendezvous Regatta when we all encountered

that previously unknown "Sea-Tittie" in the course. That personally is

another safety related issue that I have with the uni

t that is unrelated to strength and reliability.

I will assume that you are going to forward what I'm writing here so

I will try and keep it in simple terms. I will comment on the 3 points

of weakness made earlier.

1: too fine a pitch. This is a long subject. Understand that with any

"screw" mechanism you are balancing effort and strength with function.

The choice between a fine or coarse pitch screw is based on several design

criteria.

A screw is basically one of the oldest of mans tools, the inclined

plane, wrapped around a shaft. The pitch translates through diameter to

angle of incline. The greater the pitch, helix angle, the steeper the incline

and the greater the effort to raise the load. A finer pitch has a lower,

easier, angle so less effort. This is however relative to diameter. Using

the standard keel lifting screw for example, it is of 18mm diameter with

3mm pitch, it moves the screw 3mm for every turn. It has a helix angle

of approx. 3 degrees. An 18mm x 4mm screw has 4 degrees of helix, more

angle more effort. A 20mm x 4mm screw has a 3.6 degrees helix angle. Less

angle than an 18mm screw of the same pitch thus less effort more strength

than an 18mm x 4mm. About 20 fewer turns than the 18mm x 3mm. With standard

nuts and bolts there are "fine and coarse" pitches available as standard.

The primary reason for use of a fine pitch is that tha mall diameter of

the screw thread is larger and thus stronger. Also tha helix angle is less

so it does not unwind or come loose as easy. The load holding capability

though is roughly equal because of the surface area of thread engagement

is roughly equal. 5 threads of a wide depth has the equal surface area

as 10 threads of a shallow depth. The kicker comes when you factor in wear

which is not and issue in a "nut and bolt" application but IS in a screw

used for POWER TRANSMISSION. Surface wear affects a fine pitch the same

as a coarse pitch, ths fine pitch just has THINNER threads. As they wear

they get even thinner till the cross section is too weak to support the

load. Then they shear. That is the inevitable failure mode.

2: too short a length of thread engagement. Standard mecahnical practise

for "nut and bolt" applications are a length of engagement to equal 1 thread

diameter. For POWER TRANSMISSION applications that increases to a minimum

length of 1.5 times the thread diameter. The reason is to allow for the

reduction of thread cross section and strength due to wear.

3: too small a screw diameter. While the screw as is, is strong enough

to support the load, a larger one will support it better. It will also

allow you to go to a coarser pitch, which raises the keel with fewer turns,

with out greatly increasing the effort invovled over the smaller diameter

screw. Bronze has about 60% of the mechanical strength of steel or stainless.

It does have some natural lubricity. Also you do not want to use stainless

on stainless because without proper lubrication, it WILL SEIZE and stick.

Bronze is a good choice though if the structural section is adequate. From

my examination of the components a 20mm screw will fit with out any modifications

to other components. A 4mm pitch will have a bit more effort than the 3mm

BUT, WORK = WORK. 60 turns to lift 700 lbs at a more agressive rate equals

the combined effort of 80 turns to lift 700 lbs at an easier rate. You

also must realize that the coefficient of friction of bronze to stainless

steel is such that 35%-40% of the effort that you feel when turning the

crank is just to over come friction. Also as the device uses a winch handle

to actuate it would be wise to buy a 10" handle, for greater leverage,

over the supplied 8" handle.

Now that everyone knows more than they ever wanted to know about power

screw mechanisms, and I'm tired of typing, I'll leave it for now. Damned

dead horse, no matter how many times I kick it, it stays dead.

------------

Rod,

This summer I noticed my keel getting harder and harder to raise each

time I went out. The owners manual didn't mention lubricating the threads,

only the bearing. So I poked around until I realized that I could pour

oil down the hole where the winch handle sits and it would coat the threads.

I used SAE 30 motor oil because it's what I had handy. This worked great

so far and now the keel comes up smoothly once again.

Jay Harrell

------------

Jay,

Would "white grease" such as used on power seat screw gears in automobiles

work better than SAE 30 Engine Oil?

Terry

------------

Terry,

It might, however, it would be impossible to get the white grease down

in the lub hole in the lifting mechanism at the keel trunk. SAE 30 wt oil

is readily available and can be easily put into the shaft oiling hole any

time...once a month or every time we go sailing...whatever's needed.

Jay

------------

(edited and paraphrased by T. Ellis)

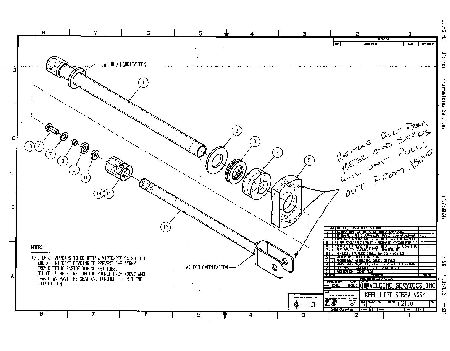

Hi res image click here

Title: Replacing Swing Keel Lifting Mechanism

Model(s): First 210

System(s): Keels

Author: Terry F. Ellis

updated May 12, 2004

|