Beneteau 211 Keel Servicing

alansm04@yahoo.co.uk

Note: This is an account of my experience and

not a ‘good practice guide’. Seek professional assistance if you are unsure

about your ability!

My First 211 is 12 years old and used in salt

water. The keel has been progressively noisy, making clanking sounds in rough

waves. I noticed that it was leaning to one side by several degrees when placed

on the trailer this year so I decided to replace the keel pivot, nylon bushes

and angle brackets.

My First 211 is 12 years old and used in salt

water. The keel has been progressively noisy, making clanking sounds in rough

waves. I noticed that it was leaning to one side by several degrees when placed

on the trailer this year so I decided to replace the keel pivot, nylon bushes

and angle brackets.

I decided to do the work from my trailer by raising the boat 50mm on Styrofoam

pads which gives just enough clearance. The hardest part of this job is

breaking the seal between the brackets and hull. It eventually released by

levering the keel up and down with a crowbar and using the full weight of the

keel.

The job was reasonably straight forward but the new bracket holes didn't align

correctly which was a bit of a pest to say the least! CHECK THE HOLE

ALIGNMENT BEFORE APPLYING ANY MASTIC! The brackets were ordered from Beneteau and £50 a piece. They are 10mm galvanised mild

steel (not Stainless). If I did this again I'd have the new brackets fabricated

in stainless.

When I removed the old brackets I was alarmed

to see how corroded and oval the holes had become. Another season could have

resulted in the keel falling out!

The nylon parts and the original stainless steel pivot pin were all in perfect

condition which makes me think that all the pivoting has been between the

stainless steel pin and the mild steel brackets. I had to cut the nylon bearing

through the keel as it wouldn't budge. The pivot hole through the keel was

sound with no rust. I also decided to fit a zinc anode to help protect against

future rust.

I painted the pivot holes on the angle brackets before inserting the new pin

and greased the main nylon bearing to ensure that the pivoting would be in the

correct place in future. I used plenty `Sikaflex

marine sealant 291' to ensure a good seal around the bolts.

This job although daunting is reasonable straight forward if planned well.

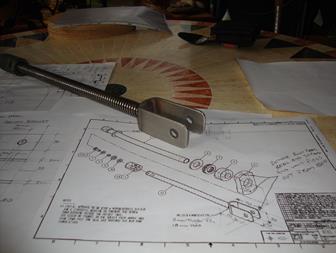

I also had to repair the keel lifting mechanism as the fork was damaged and the

bolt badly corroded. This is an M12 bolt with Nyloc

nut (17mm spanner) This job can’t be done on the trailer but is easily accessible when the boat

was lifted for launching. My local blacksmith fabricated and welded on a new

stronger SS fork for £30.

I had my first sail of the season yesterday and the boat has a much stiffer

feel - with no clanking noise. (No leaks around bolts following first sail - phew!)

November 2003 Update: Had a really good season

with plenty of exciting sailing. Still no noise from keel

& no water ingress. A job worth doing.

Alan